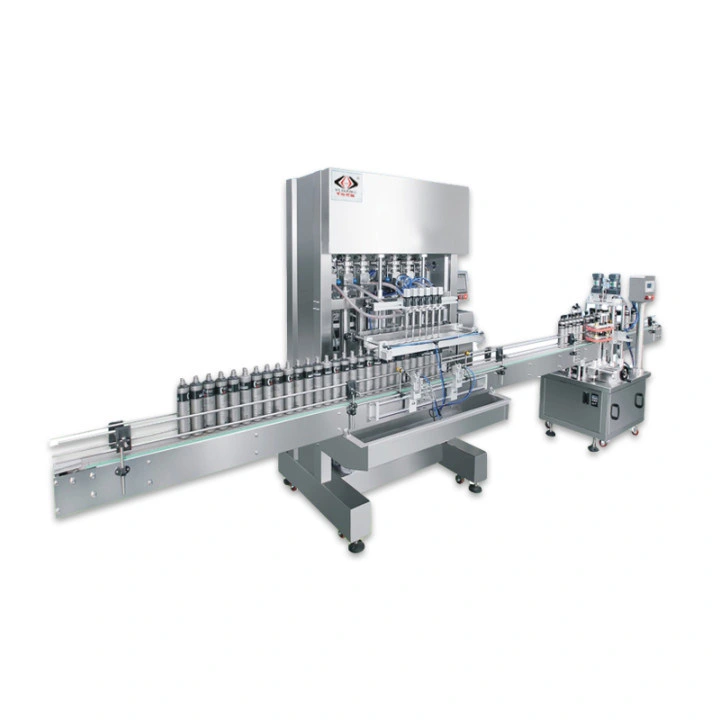

Yuhang Automatic Filling and Capping Machine

It is suitable for tea, dairy products, liquid food, energy drinks, milk tea, coffee and other products.

We have very high requirements for production equipment. Yuhang filling and capping machine will provide

different solutions for different products. Each of your products has its own optional solution.

Would like to know more about YUHANG Machine equipments, feel free to send us an inquiry!

Automatic Filling Machine

Wide range of applications:

Characteristic:

1.Touch screen operation

2.Special filling valve design, filling without leakage

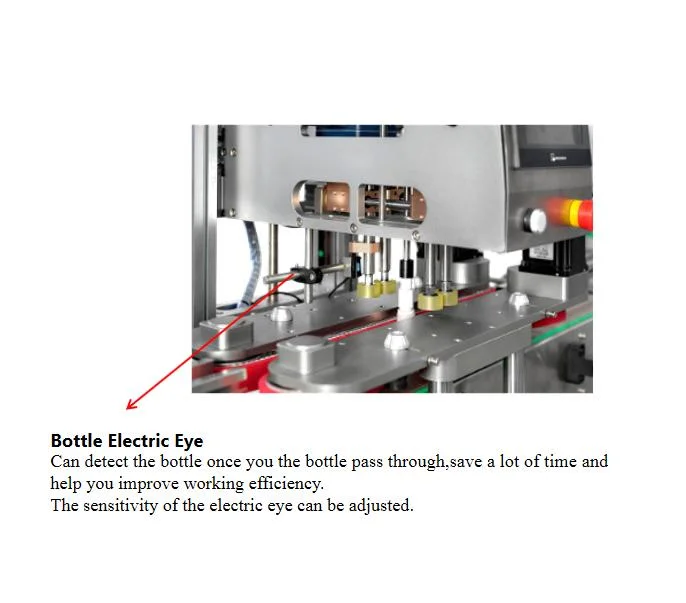

3.No bottle or lacking bottle will not filling

4.Adopts the imported electronic to control, conveyor has frequency conversion speed adjuster.

5.Whole machine make by SUS 304 stainless steel

6.Has the glass protection cover, safe and sanity.

Automatic Capping/Closing Machine

Complete and independent machine, designed for the execution of capping processes at adjustable speed

with a universal range of capping: Triggers, Dosers, Screw.

Capping unit adjustable in width and height according to the cap, bottle inlet and outlet sensors.

The machine can be equipped with an automatic caps loading system.

It is suitable for tea, dairy products, liquid food, energy drinks, milk tea, coffee and other products.

We have very high requirements for production equipment. Yuhang filling and capping machine will provide

different solutions for different products. Each of your products has its own optional solution.

Would like to know more about YUHANG Machine equipments, feel free to send us an inquiry!

Wide range of applications:

Now our products are widely used in food,medicine,manufacture,printing,logistics and other industries,

They are used inproduction's quality inspection, classification, as well as in the product packaging weigher test.

They had helped customers togreatly reduce the labor costs, to improve the production efficiency, and greatly to

improve the percent of pass, help customers to improve the industry competitiveness.

They are used inproduction's quality inspection, classification, as well as in the product packaging weigher test.

They had helped customers togreatly reduce the labor costs, to improve the production efficiency, and greatly to

improve the percent of pass, help customers to improve the industry competitiveness.

| Pressure | 220V/380V |

| Air pressure | 0.4-0.6Mpa |

| Filling range | 100-1000ml (Customized) |

| Speed | 20-40 bottles/min |

| Filling accuracy | ±1% |

Characteristic:

1.Touch screen operation

2.Special filling valve design, filling without leakage

3.No bottle or lacking bottle will not filling

4.Adopts the imported electronic to control, conveyor has frequency conversion speed adjuster.

5.Whole machine make by SUS 304 stainless steel

6.Has the glass protection cover, safe and sanity.

Automatic Capping/Closing Machine

Complete and independent machine, designed for the execution of capping processes at adjustable speed

with a universal range of capping: Triggers, Dosers, Screw.

Capping unit adjustable in width and height according to the cap, bottle inlet and outlet sensors.

The machine can be equipped with an automatic caps loading system.

The Full automatic capping machine is one kind of packaging machine in the filling production line.

It is applied to the medicine, beverage, Cosmetic, Chemical and other product for capping the bottles.

Key Features

- Compressed air powered*

- Up to 40 bottles/min throughput

Suitability

- Small to medium scale production

- Free flowing liquids (perfumes, spirits, etc)

- Medium viscosity liquids (shampoos, lotions, light creams)

- Viscous syrups and adhesives

- Liquids containing particles (e.g. food products)

- * Applies to most semi-automatic machine